Global Information

Global InformationReflow soldering information

This article needs additional citations for verification. (December 2010) |

Reflow soldering is a process in which a solder paste (a sticky mixture of powdered solder and flux) is used to temporarily attach anywhere from one to thousands of tiny electrical components to their contact pads, after which the entire assembly is subjected to controlled heat. The solder paste reflows in a molten state, creating permanent solder joints. Heating may be accomplished by passing the assembly through a reflow oven, under an infrared lamp, or (mainly for prototyping) by soldering individual joints with a hot air pencil.

Reflow soldering with long industrial convection ovens is the preferred method of soldering surface mount technology (SMT) components to a printed circuit board (PCB). Each segment of the oven has a regulated temperature, according to the specific thermal requirements of each assembly. Reflow ovens meant specifically for the soldering of surface mount components may also be used for through-hole components by filling the holes with solder paste and inserting the component leads through the paste. Wave soldering however, has been the common method of soldering multi-leaded through-hole components onto a circuit board designed for surface-mount components.

When used on boards containing a mix of SMT and plated through-hole (PTH) components, through-hole reflow, when achievable by specifically modified paste stencils, may allow for the wave soldering step to be eliminated from the assembly process, potentially reducing assembly costs.[clarification needed] While this may be said of lead-tin solder pastes used previously, lead-free solder alloys such as SAC present a challenge in terms of the limits of oven temperature profile adjustment and requirements of specialized through-hole components that must be hand soldered with solder wire or cannot reasonably withstand the high temperatures directed at circuit boards as they travel on the conveyor of the reflow oven. The reflow soldering of through-hole components using solder paste in a convection oven process is called intrusive soldering.

The goal of the reflow process is for the solder paste to reach the eutectic temperature at which the particular solder alloy undergoes a phase change to a liquid or molten state. At this specific temperature range, the molten alloy demonstrates properties of adhesion. Molten solder alloy behaves much as water, with properties of cohesion and adhesion. With sufficient flux, in the state of liquidus, molten solder alloys will exhibit a characteristic called "wetting."

Wetting is a property of the alloy when within its specific eutectic temperature range. Wetting is a necessary condition for the formation of solder joints that meet the criteria as "acceptable" or "target" conditions, while "non-conforming" is considered defective according to IPC.

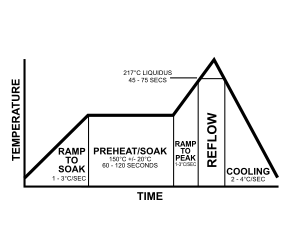

The reflow oven temperature profile is suited for characteristics of a particular circuit board assembly, the size and depth of the ground plane layer within the board, the number of layers within the board, the number and size of the components, for example. The temperature profile for a particular circuit board will allow for reflow of solder onto the adjoining surfaces, without overheating and damaging the electrical components beyond their temperature tolerance. In the conventional reflow soldering process, there are usually four stages, called "zones", each having a distinct thermal profile: preheat, thermal soak (often shortened to just soak), reflow, and cooling.